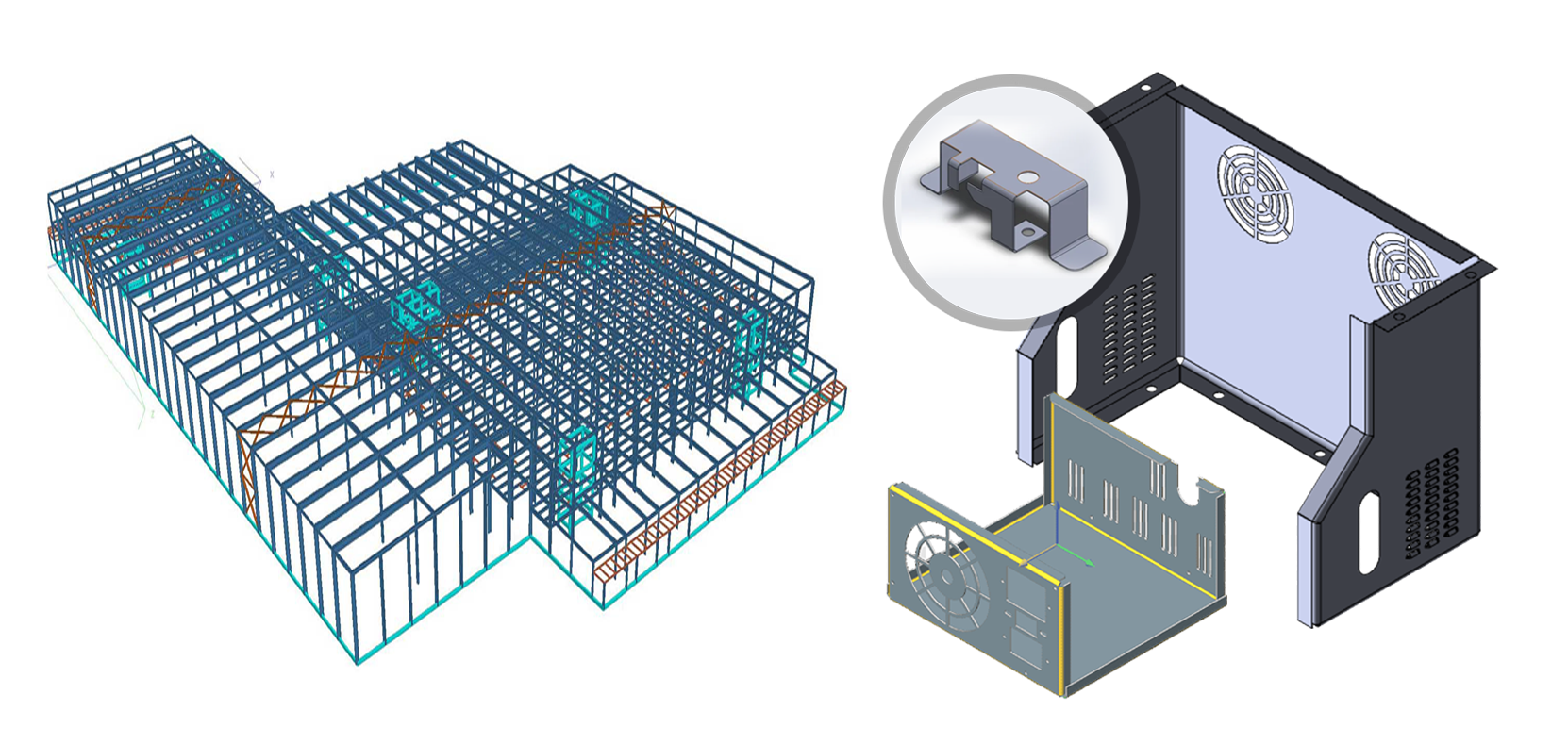

Silicon Engineering Consultants Pty Ltd delivers quality-reliable Sheet Metal Detailing Services to mechanical designers, HVAC contractors, builders, fabricators, MEP engineers, and various technical consultants and site engineers. We provide high-quality-cum-affordable CAD and BIM-based sheet metal detailing solutions that make the production and installation of complex thin metal parts achievable for our clients. Using Solidworks, Revit, Tekla, 3DS Max, Inventor, and other remarkable software to produce customized sheet metal designs and BIM models. Our Sheet Metal Detailing Services encompass metal parts drawing requirements for HVAC systems, automotive industry, architecture, industrial equipment, furniture manufacturing, aerospace, medical equipment, transportation & railways, signage & display, and much more.

Our qualified team considers factors like deadlines, approvals, compliance codes, customization, and more when providing Sheet Metal CAD Services to address every technical specification with professionalism. Throughout our service provision, we support clients with transparent reporting, responsive engagement, and dependable turnaround schedules. We provide sheet metal CAD drawings in compatible formats in optimized file sizes to make sure our clients can use them instantly without dealing with oversized files or compatibility issues. Our whole Sheet Metal Detailing Services process revolves around meeting building and construction standards, covering every dimensional detail, connection type, and compliance checklist.

With the increasing intricacy of architectural and mechanical components, the requirement for durable and as well aesthetically pleasing sheet metal has grown across modern infrastructure and manufacturing projects. Our team understands that creating complex bends, curved surfaces, compound contours, louvered features, and multifaceted junctions isn't about pushing CAD boundaries alone—it's about knowing how each form behaves during fabrication. Our Sheet Metal Design Services include CAD plans for a wide variety of forming processes—including stamping, CNC folding, rolling, press forming, and hydroforming. Through AutoCAD Sheet Metal Design Services and Solidworks Sheet Metal Design Services, we make sure to fully address tooling compatibility, assembly fit, and design constraints.

At Silicon Engineering Consultants Pty Ltd, our Autocad Sheet Metal Drawings Services strategize around preparing concise, ready-to-fabricate flat patterns customized to your project's manufacturing process. Through Sheet Metal 2D Drawings Services, we provide thorough specifications on bend radii, K-factors, thickness compensation, and machine-specific tolerances that make the final output more consistent. We cover the requirements for aluminum, stainless steel, or coated metal-based designs during Sheet Metal Drawing Solidworks Services to examine the material's behavior and the shop's forming capability. In addition to that, we offer Inventor Sheet Metal Drawings Services that support unique corner relief methods and unfolding logic compared to SolidWorks.

Our Sheet Metal Detailing Services workflow is strategic and full of feedback and consistent modification. We allow our clients to refine designs continuously based on functional needs and fabrication feasibility. When working on AutoCAD Sheet Metal Design Services, always endeavor to design intricate metal sheet designs for real-world execution—not theoretical perfection. Solidworks Sheet Metal Design Services and Inventor Sheet Metal Drawings Services empower clients to take a step forward in making projects productive with collaborative detailing support and real-time design updates.

Contact us if you're looking for consistency and adaptability in sheet metal detailing. We prepare 2D and 3D drawings as per your project's needs. Our Sheet Metal Detailing Services, Sheet Metal CAD Drawings Services, and Sheet Metal Solidworks Drawing Services help you meet project accuracy benchmarks and optimize material usage.