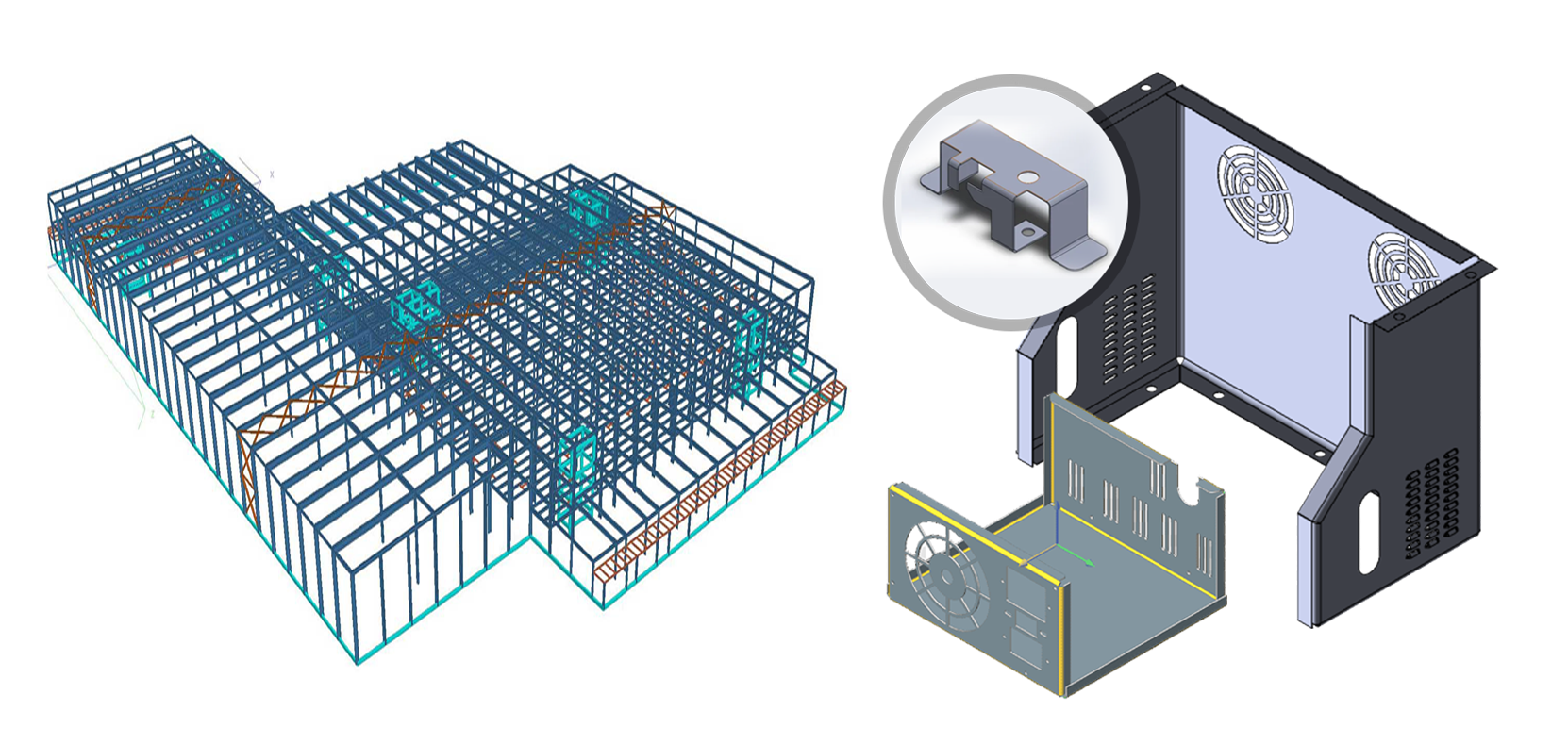

Silicon Engineering Consultants Pty Ltd has a separate division of sheet metal shop drawing and drafting teams that reinforce years of experience by handling complex geometries with technical accuracy. We offer quality-assured Sheet Metal Shop Drawings Services at reasonable pricing so the initial obstacle of clients in budgeting is removed without compromising quality. We assist fabricators, mechanical engineers, architects, builders, and retailers in identifying material cut lists and part dimensions directly from our detailed sheet metal CAD drawings. Additionally, our Sheet Metal Fabrication Drawings Services enhance communication between design, fabrication, and assembly teams through clear, coordinated documentation.

Beyond Sheet Metal Shop Drawings Services, we provide a complete range of Sheet Metal Drafting Services support to engineers aiming to optimize functional, lightweight, and economical metal parts. Our quality-committed team works with Solidworks, Inventor, Revit, Tekla, and other advanced software in Sheet Metal Engineering Drawing Services workflow to create accurate bend allowance calculations and unfolding for productive metal sheet forming. We follow AS 1100.101, AS 1100.201, AS 1562.1, AS/NZS 4254.1, and other regional standards to guarantee the durability and safety of all sheet metal work. Correspondingly, our Sheet Metal Shop Drawings Services emphasize quality and meet standards to deliver dependable drawings that meet project timelines and budget goals.

Sheet metals are very fine in thickness, and even a small measurement issue can reduce durability and functionality. Through our Sheet Metal Fabrication DrawingServices, we design fabrication-ready plans so accurately that when manufacturers produce metal sheets at scale, they receive zero-fit issues and an error-free transition from digital drawings to physical fabrication. Our Sheet Metal Fabrication Design Services also contribute to material takeoffs and quantities, ensuring manufacturers receive exact input for pre-production planning. During our Sheet Metal Fabrication Drawings Services, we test various materials based on client requirements in 3D simulation software to assess deformation risks and prevent warping during cutting or forming. Below are crucial specifications we deliver with Sheet Metal Fabrication Drafting Services to eliminate errors during manufacturing:

Where shop drawing solutions focus on communicating fabrication-ready geometry and assembly intent, our custom Sheet Metal Drafting Services help in building those drawings from the ground up to match specific metal sheet requirements, tooling processes, and product goals. During Sheet Metal Drafting Services, our team accounts for every factor that influences the final product: bend radii, tolerances, material thickness, welding seams, hardware inserts, and structural orientation. In terms of readability and documentation conciseness, our Sheet Metal Drafting Services focus on clarity and brevity to make technical details accessible to all project teams.

Get sheet metal shop drawings that speak your fabricator's language—no confusion, no errors—just concise, ready-to-fabrication, and assembly clarity. Reach out to our team regarding custom Sheet Metal Shop Drawings Services and Sheet Metal Drafting Services.